Quality Materials That Make Custom Patches Last for Years

Imagine one day, you hand-sew a Taylor Swift-inspired patch onto your jacket, and it’s not even day 5 that it starts coming off. Who is to blame?

- The sewing technique.

- The fabric choice.

- Or the vendor.

Of course, the fabric choice is the culprit because even if your stitches were flawless and the vendor swore by their expertise, a weak fabric will betray you.

It won’t grip the thread, it will fray quickly, and your patch? Gone by the end of the week. Therefore, choosing a sturdy, patch-friendly fabric is not just smart. It’s essential. This blog will guide you through five excellent options to choose from, along with some other useful insights.

Choosing the Right Fabric for Custom Patches: 5 Choices

It is no secret that people are head over heels in love with custom-made embroidery patches Canada. Be it a concert, get-together, casual dine-out, or even a themed office party, they are the most popular style statement. All due to the bold, personal, and impossible-to-ignore look.

But here’s something most users overlook: the fabric beneath the design is what truly makes or breaks your patch. Perhaps this is the reason why even a stunning pattern sewn onto the wrong material will fade, fray, or fall off before you have even posted the OOTD on Instagram.

So, think of the material far more than just a detail. It is the foundation that keeps your badge intact even after several washing cycles, climate exposures, and all the tugs and pulls.

Material Number 1: Twill

- Cost: Budget-friendly

- Features: Smooth surface, easy to embroider

- Benefit: Durable and versatile

Experts don’t just call this fabric ‘the number one choice’ for no reason. It is the most go-to textile for custom patches. We mean, look at it: tough enough to handle daily wear and tear, yet smooth enough for crisp embroidery. What else can one ask for?

Hence, if you want something that balances quality and affordability, you should know that twill delivers. It is perfect for uniforms, team gear, or everyday branding. Plus, it holds color well. So, your design stays alive even after repeated washes.

Material Number 2: Felt

- Cost: Moderate

- Features: Soft texture, retro appeal

- Benefit: Adds warmth and depth

For the die-hard fans of softer badges, felt is the most suitable material. Unlike rubber patches Canada, it brings a cozy, old-school vibe to your patches. In addition, it is not just soft to the touch, but it also adds a rich, tactile feel that elevates the overall outfit vibe.

Hence, felt is ideal for fashion-forward brands or nostalgic styles. It is also great for indoor wear or decorative patches because it offers a unique aesthetic that stands out.

Material Number 3: Canvas

- Cost: Affordable to mid-range

- Features: Heavy-duty, textured, and tough.

- Benefit: Withstands tugs and pulls.

With the evolution of embroidery, the world of fashion needed a stronger and reliable foundation to carry the designs. This meant the badge material had to support the weight of the thread. They also needed to hold the shape of the patterns. Without that support, the embroidery would lose its impact. So, fashion turned to materials like canvas, which could handle both beauty and strength. This unsung hero is weather-resistant and holds up beautifully under stress. Therefore, even if you are wearing them outdoors, there is a higher chance that they will remain intact.

Material Number 4: Denim

- Cost: Mid-range

- Features: Thick weave, casual, and cool

- Benefit: Built to last

Denim is not just for jeans. It makes an awesome and sturdy patch base, too. This is because it is a thick weave that resists fraying and fading. Hence, it is perfect for high-impact use.

So, whether you are going for a streetwear look or something industrial, denim is the right material for your badges. It will not only add texture but also a bit of cool attitude. Simply put, it is great for jackets, bags, and gear that sees a lot of action.

Material Number 5: Leather

- Cost: High-end

- Features: Sleek, luxurious finish

- Benefit: Makes a statement

Last but not least, the leather patches scream premium quality. They are bold, yet elegant, and instantly elevate your brand game. However, they are on the pricier side. Apart from this, it takes special machines to embroider on them, too, but the final results are worth it all.

Furthermore, leather material resists climate exposures and adds a timeless edge to your badges. So, if you want your patch to feel like a badge of honor, leather’s the way to go.

A Table to Show How Much Each Fabric Is Used

| Fabric Type | Usage Frequency |

| Twill | ***** |

| Felt | *** |

| Canvas | **** |

| Denim | **** |

| Leather | ** |

Key:

- 1 – means least used

- 2 – means rarely used

- 3 – means moderately used

- 4 – means frequently used

- 5 – means the most used

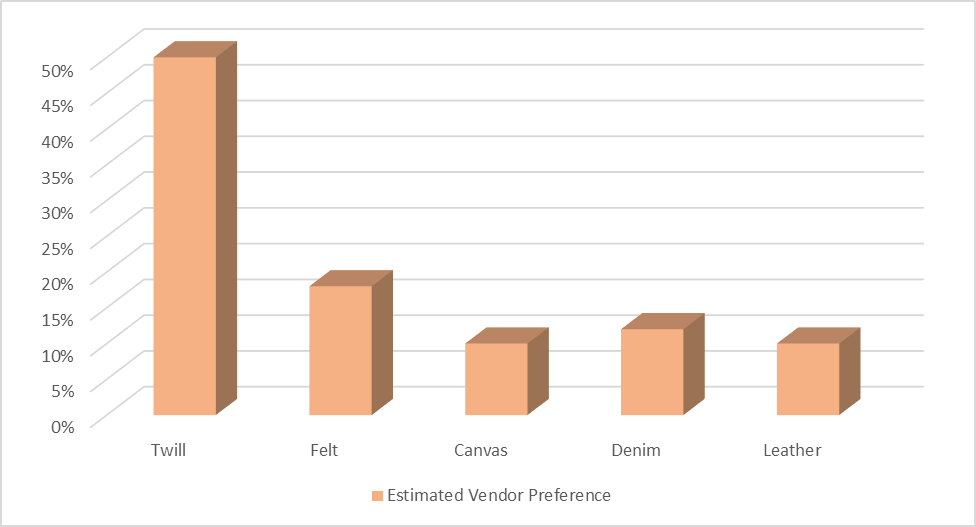

Vendor Preferences for Patch Materials

The graph shows how twill is one of the most commonly used options for embroidered patches because of its durability and cost-effectiveness. However, canvas and leather are only valued for their premium aesthetics.

This means they are less commonly used due to cost and complexity. Felt and denim, on the other hand, are niche favorites for fashion-forward and artistic designs. Thus, they are your best materials if you are looking for sifter textures and trendy appearances.

Some Other Materials That Can Also Do the Job

PVC (Rubber)

PVC patches are exceptionally durable and waterproof, making them ideal for outdoor gear, tactical uniforms, and accessories exposed to harsh environments.

Chenille

They are often associated with sports apparel and offer a thick, textured surface that is both visually outstanding and structurally resilient. Hence, despite its soft appearance, it holds up well when backed with sturdy materials.

Nylon

Known for its strength-to-weight ratio, nylon is a practical choice for badges on activewear, backpacks, and technical garments. It can resist abrasion and moisture, too.

Woven Fabric

They are created by tightly interlacing threads, which means they allow for precise detail and clean lines. They also offer a flatter profile and are well-suited for logos or designs requiring longevity.

The Final Words on Patch Materials

Speaking of the right material for your next badge, it is essential to understand that the foundation fabric should be durable, resistant, and sturdy. Then only the cute little patch will stay intact throughout the weather conditions and wear and tear.

Hence, you must go for strong options like twill, nylon, canvas, denim, and woven fabric because they offer everything you are searching for. Moreover, each of the materials mentioned in the blog serves a distinct purpose. So, think twice before making a final decision.