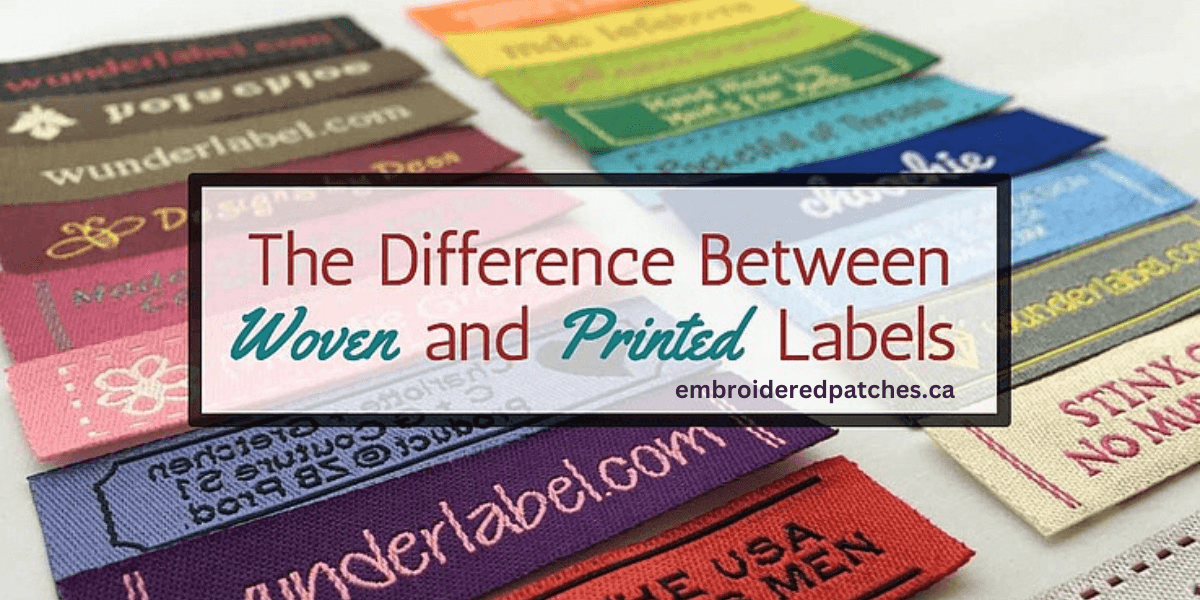

Imagine wandering through a vibrant, bustling marketplace surrounded by a sea of colourful garments. As you browse the racks, your glance is captured towards two identical shirts. You look at them closely, and that’s when you notice the slight difference – one has beautifully woven labels, while the other showcases an eye-appealing printed one. A question bubbles up in your mind: Which label is the best? Thus, let’s unravel its answer by exploring both advantages and disadvantages.

A Detailed Comparison Between Woven And Printed Labels

Woven Labels: Introduces Classic Touch

Woven labels represent quality craftsmanship, usually chosen for expensive apparel, designer brands, and luxury products. They are sewn into the fabric, creating a smooth integration with the garment itself. Let’s delve into the advantages and limitations of woven labels:

Top 5 Advantages Of Woven Labels

- Durability: Woven labels are highly durable. The complex knitted threads ensure the creation stays in place even after numerous washes, maintaining its beautiful appearance. The woven label will neither fade nor fray over time, making it perfect for frequently washed clothing.

- Offers Elegance: Unlike printed labels offering vibrant versatility, woven ones provide timeless elegance. The fine details and complex designs achieved through weaving introduces gracefulness to any garment, thus elevating its overall aesthetic appeal.

- Tactile Texture: One of the unique characteristics of woven labels is their texture. The raised threads create a tactile experience, which allows consumers to feel the quality of the label. This touchable feel enhances the overall value of a product.

- Customization For Branding: These cotton-made thread creations offer various customization options, helping brands to showcase their logos, slogans, etc. They serve as a powerful branding tool, boosting brand awareness and creating a lasting impression in the minds of consumers.

- Versatility: Woven labels merge smoothly into various garments, accessories, and home textiles. You can adhere to fabrics and styles, from delicate lingerie to durable denim. Thus, it is a favourite versatile choice for designers and manufacturers.

5 Major Disadvantages Of Woven Labels

- Production Costs: The intricate weaving process in creating woven labels can be more time-consuming and expensive than printing techniques. Thus, these cotton-made creations are not friendly for individuals or businesses on shoe-string budgets.

- Limited Color Palette: Unlike printed labels, woven ones have certain limitations regarding colour reproduction and can’t offer vibrant and complex colour schemes. Thus, this disadvantage pushes away the brands that want to achieve vibrant coloured creations.

- Design Complexity: While woven labels excel in capturing fine details, they are unsuitable for highly intricate or complex designs. The weaving process may fail to create tough logos or graphics, ruining the label’s visual appearance.

4. Size Restrictions: Creations made with cotton are unsuitable for small or delicate garments with limited space. The size restrictions may also limit design choices for specific products.

- Production Duration: The production of woven labels often involves a longer duration due to the complexity of the weaving process. Brands that require quick turnaround times or have tight production schedules usually incline towards printed creations due to their speedy production.

Printed Labels: Vibrant Versatility

We shed light upon the advantages and disadvantages of woven labels; now, it is time for the printed ones. Wading through the following sub-headings will create an in-depth comparison between both types in your mind.

Top 5 Advantages Of Printed Labels

- Broader Colour Schemes: Printed labels offer colourful and more comprehensive colour schemes, making them ideal for brands relying on vibrant elements. Printing allows for desired hues contrast, allowing you to represent your logos, graphics, and designs accurately.

- Myriad Design Possibilities: The sky’s the limit regarding design possibilities with creations made from digital printers. They can quickly craft minute details and complex designs from gradient effects to photorealistic images. For instance, if you want personalized keychains, all these features of printed make it the perfect option for the woven type.

- Budget-Friendly: Creations made from digital printers are often budget-friendly compared to woven. The printing process can be faster and requires fewer resources, making it a cost-effective option for brands.

- Small Size Availability: Printed labels offer complex designs even in smaller sizes without compromising appearance. This feature allows businesses to incorporate these creations smoothly into their designs without worrying about size restrictions.

- Quick Turnaround: Printing techniques generally have a shorter production duration than weaving. Therefore, brands prefer printed creations to meet tight deadlines and respond quickly to market demand.

5 Major Disadvantages Of Printed Labels

- Durability And Wash Fastness: Woven win over printed labels for the highest durability. While printing technology advancements have improved creations’ longevity, they still fade or peel over time. Frequent washing or exposure to harsh conditions can fastly damage the artistic pieces.

- Lacks Tactility: Unlike woven labels, printed labels lack the tactile experience that comes with raised threads. The smooth surface of printed labels may not provide the same touchable feel as woven.

- Limited Fabric Compatibility: Certain printing techniques may not suit all fabrics. For example, heat transfer printing may not attach to textured or stretchy materials. You must consider the compatibility between printing methods and clothing materials not to let your money wasted.

- Inadequate Customization For Branding: Creations made through printing techniques may require adjustments when applied to different products or fabrics. The printing process may not offer the same versatility for customization that suits various brands as woven labels. Therefore, the process needs additional changes for different applications.

- Brand Recognition: Printed labels are usually visually appealing but may not play the same role in brand recognition as their woven counterparts. Hence, when choosing between the two options, brands should weigh the importance of brand awareness and perception.

The Final Verdict: Choosing The Right Label

When selecting woven and printed labels, there is no straight answer as to which is best. Before picking the option, you must consider various factors, including the brand’s identity, target market, product type, budget, et cetera. Woven offer durability, elegance, and a tactile experience, which makes them an excellent choice for expensive and timeless products.

Yet, printed labels are versatile, vibrant, and budget-friendly for branding, mostly used in casual wear to promotional items. Thus, pick them if you want a durable, softest, rich, tactile textured piece for your luxurious product. In contrast, get a vibrant and intricate printed label, which is friendly for your tight budget and perfect for fast fashion.